Electrical Engineering

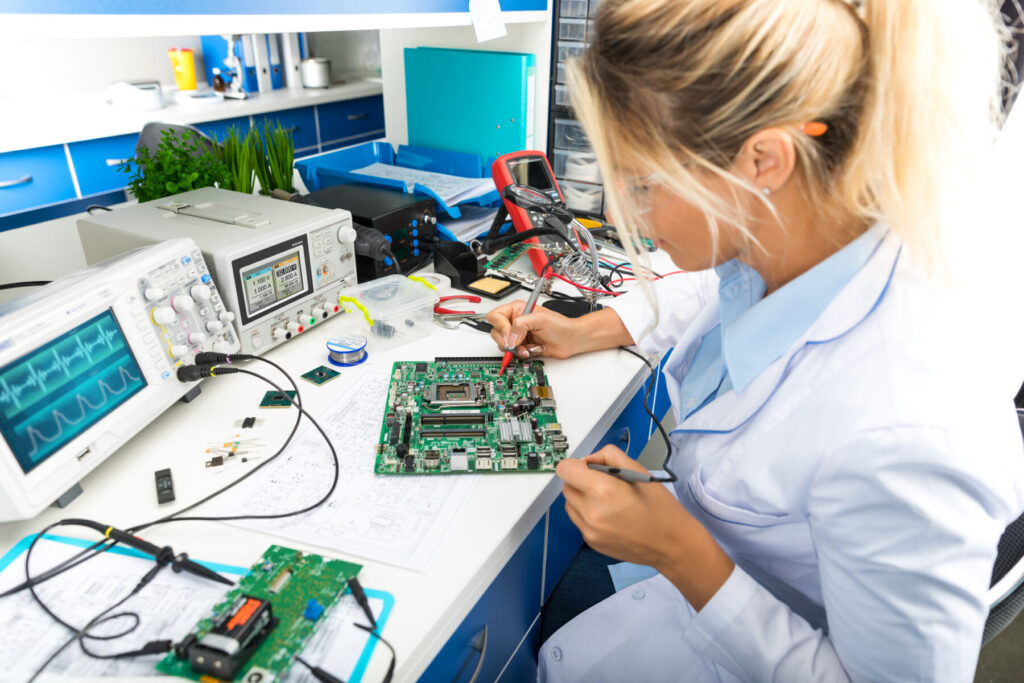

At Sparx, our engineers are engaged in a project from start to finish, which yields a high level understanding of all the details of design, test and production. Electronics are a critical component of any technology system. Manufacturability is a constant concern, and designs are optimized for ease of testing to minimize production steps.

Whether your design needs to be intrinsically safe or explosion proof for gas hazards, you’re designing electronics for aerospace, or you’re pursuing FDA 510K for a new medical device, we have the experience to get your product certified for global distribution.

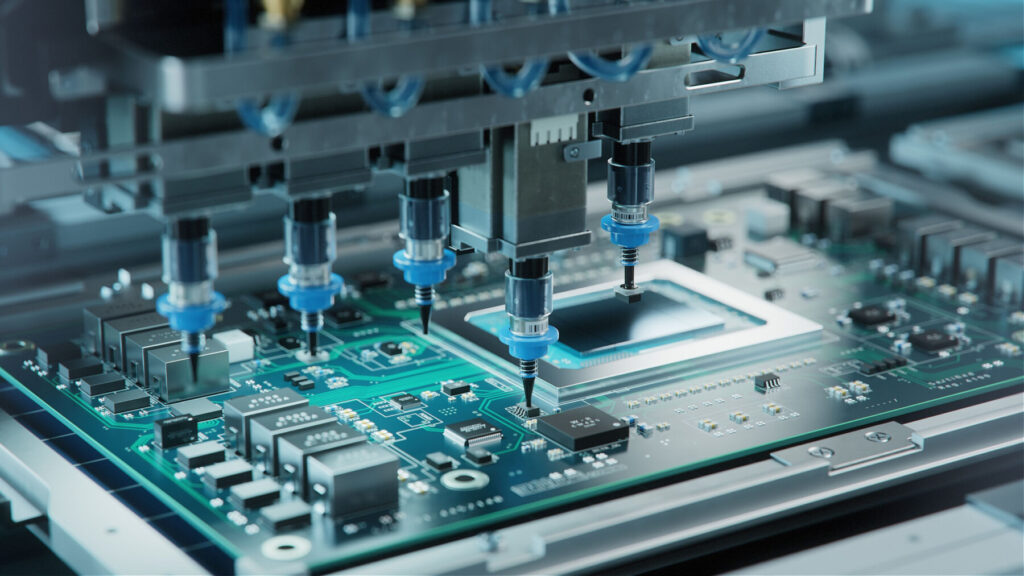

PCB Design

Custom PCB design and development with proper component selection, schematic design, and PCB layout from IPC certified engineers. Our expertise includes:

- Prototype Electronics

- Controlled Impedance and Dielectrics

- High Speed, Voltage, Current and Power

- Radio Frequencies

- Flex / Rigid Designs

- ARM and Intel Processors, and FPGAs

- Derating Analysis

- BOM Optimization

- High Density / BGAs

- Multilayer (10+)

- IPC-2221 / 2222 / 2223 Class 1, 2 and 3

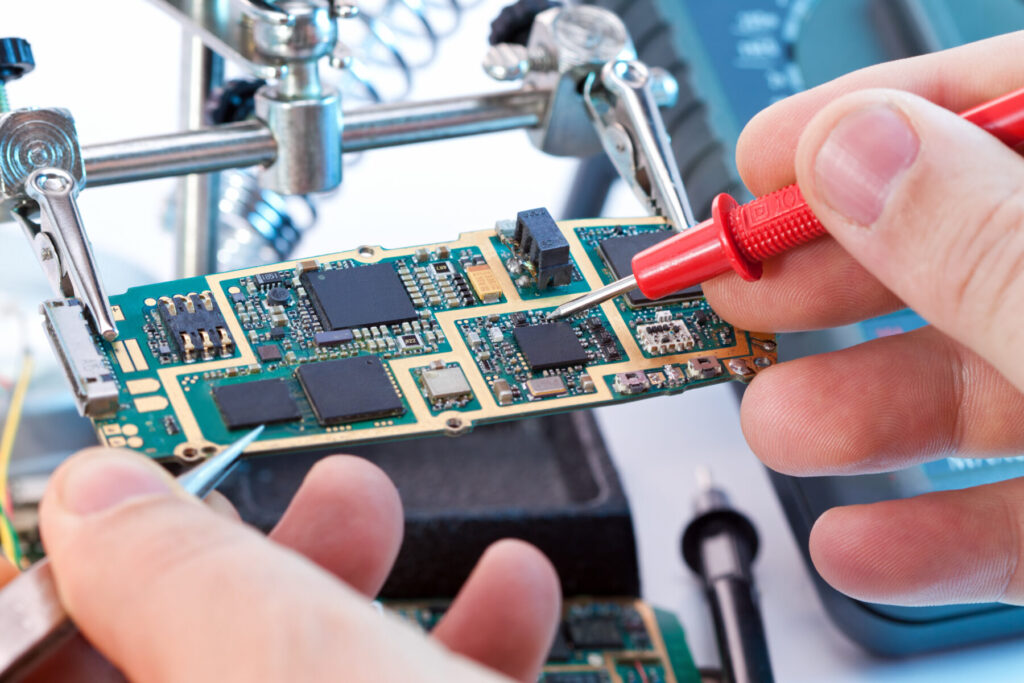

Test & Troubleshooting

Our team has both hardware and software engineers who work closely together to understand the whole system and find the best solution to your problem, not just patch around it. Our test methods focus on:

- Custom Test Firmware

- Design Review

- Divide-and-Conquer Failure Isolation

- Signal Integrity Analysis

- Circuit Simulations

- Automated Data Acquisition

- Analysis, Verification and Improvement of: Radiated and Conducted Emissions, RF Susceptibility, Insulation, Lighting and ESD Protection, Voltage Transients and Ripple, Current Inrush, Vector Network

- Iterative Testing of Subcircuits During Assembly

- Inhouse HALT Testing for High Vibration and Rapid Thermal Testing

- Design for Manufacturability and Test (DFM, DFT)

Regulatory Testing & Documentation

Sparx has experience producing the design and process documentation required to quickly move through industry certifications. Past projects have involved pre-qualification and certification to:

MIL-STD 810G, 461F, 1472G, DO-160G

FDA, FCC, CE, IC, OSHA, CPSC

Intrinsic Safety, Explosion Proof, Lithium Battery Transportation

Production Management

We can provide the manufacturers with test fixtures and procedures to assure that you only pay for finished working products.

- Cable Drawings

- Assembly Drawings

- Ladder Drawings for Custom Control Boxes

- Prototype Design Through High-Volume Production

- Range of Manufacturing Testing Developed from Paper Test Procedures to Fully Automated Custom Test Fixtures

- Knowledgable in Local and Abroad Contract Manufactures Promoting Efficiency and Cost

- Product Assurance Through Pre-Certification and Testing

- BOM Reviews and Part Replacements

- Review of PCB Assembly and Cable Manufacturing per IPC standards

- Review of PCB Rework and Cable Rework per IPC Standards

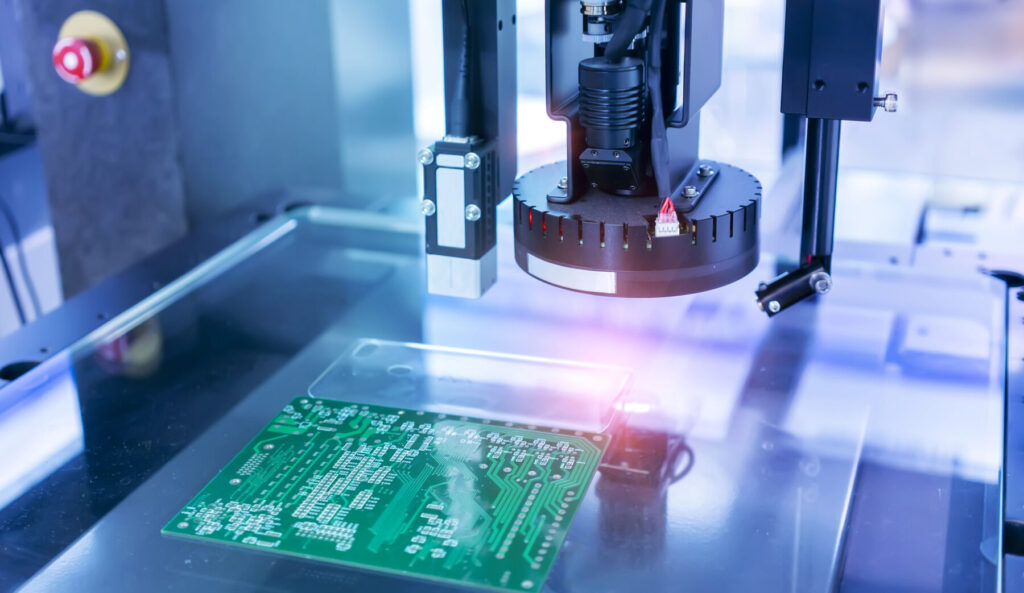

Custom Test Fixtures

Sparx has experience in the development of custom test fixtures for automating the manufacturing and testing of printed circuit boards and other components. Our test fixture architecture enables:

- Automated Testing of Individual Boards/Multi-Piece Panels

- Visible Indicators of Pass/Fail

- Integration with Label Printers

- Produce Printed Test Reports

- Automated Embedded Firmware Programming

- Integrated Barcode Reader for Serial/Part Number Identification

- Measure voltage, current, capture waveforms, inject test signals

Cable Harness Design

Sparx is skilled in producing designs for cable harnesses as well. Whether the cabling is internal to an enclosure or a rugged, industrial umbilical cable for harsh environments, we can design what your application needs. We can create cable drawings, assembly instructions, and bill of materials and any other documentation you require. We can source components, build prototypes, build cable test equipment and procedures, and work with contract manufacturers to turn your custom cable assembly into an orderable part number.

Contact Us

Our work doesn’t stop with design and manufacturing – to truly bring a product to market often means successfully achieving regulatory compliance and approval, with documented adherence to industry standards. Our on-site test equipment and test methods help us prepare for compliance testing so assure confidence in our designs before we’re at the test facilities. Similarly, we pursue field testing in real world environments to make sure that usability needs and compatibility with environmental variables are met.