Already have a manufacturing partner? We can work with whomever you prefer. If not, we can make recommendations based upon your design complexity, volume, release schedule, and budget.

RoHS VERIFICATION

- FDA, ISO, IEC, IPC

- MIL-STD 810G, 461F, 1472G

- FCC, CE, UL, OSHA, CSA

Cost Reductions

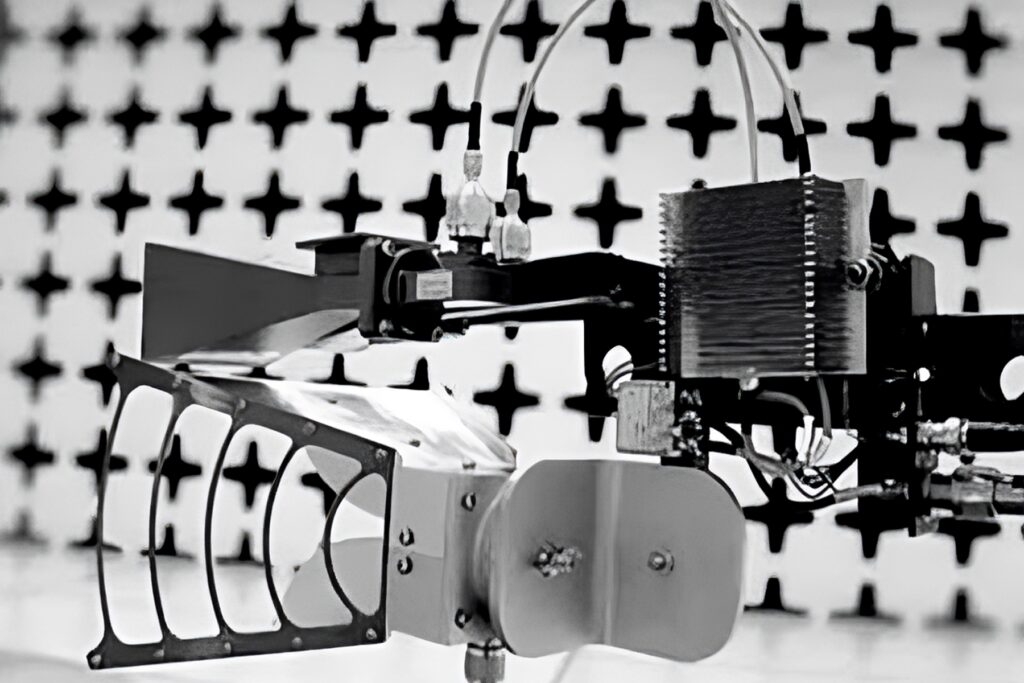

Finding where off the shelf (OTS) parts can be bought or custom designed components can be manufactured are often difficult and time consuming tasks. At Sparx, we have developed a vast vendor network across multiple industries that allow us to bring in trusted partners to assist in delivering on customer projects. Our internal prototyping capabilities also enable critical components to be machined, 3D printed, or assembled onsite to ensure the designs are suitable for the application and manufacturable in the required volume.

BOM Cost Reductions

Sparx has extensive experience in Bill of Materials (BOM) cost management. Whether redesigning a legacy product or designing a first generation prototype, pricing is always at the forefront of our design decisions. From the smallest component to the most expensive, Sparx keeps clients informed on potential tradeoffs in component selection such as availability, product lifespan, and functionality, while taking into account client expectations for design complexity, volume, release schedule, and budget.

End of Life

Product life cycle and regulatory longevity of products can often be overlooked. Sparx keeps up to date with the latest in technology trends and regulatory requirements covering industries from Oil & Gas to Medical (and the tech spaces in between). The simplest design change can have major implications on the ability to continue building a product from not only component availability level, but also in the regulatory enforcement arena.