Home » Mechanical Engineering

Our engineers can rapidly come up to speed on existing designs in order to fix problems, make modifications, or reverse engineer designs.

Rapid Prototyping

Sparx can quickly get to a “Works Like” prototype by rapid iteration and “fail-fast” methods.

- Access to a variety of additive manufacturing systems through both in house equipment and external vendors

- In house fabrication tools for quick CNC machining, 3D FDM, 3D powder and 3D SLA printer builds

- Multiple options for system controls

Advanced Simulation Analysis

- Structural and Vibration Analysis for Aerospace

- Modal, shock, static Analysis

- Finite Element Analysis for wide ranges of materials, component types and fully integrated assemblies

- Computational Fluid Dynamics (CFD) for flow analysis

- Multiphysics simulation

- Can analyze existing designs for weak points

- Analysis of complex linear, nonlinear, and weld analysis systems

Advanced Computer Aided Design (CAD)

Sparx has expert knowledge of all types of CAD software.

- Engineering drawings for manufacturing, assembly and patent documentation

- Complex assembly design

- Single part to complex assembly tolerance studies

- Photo-realistic rendering software

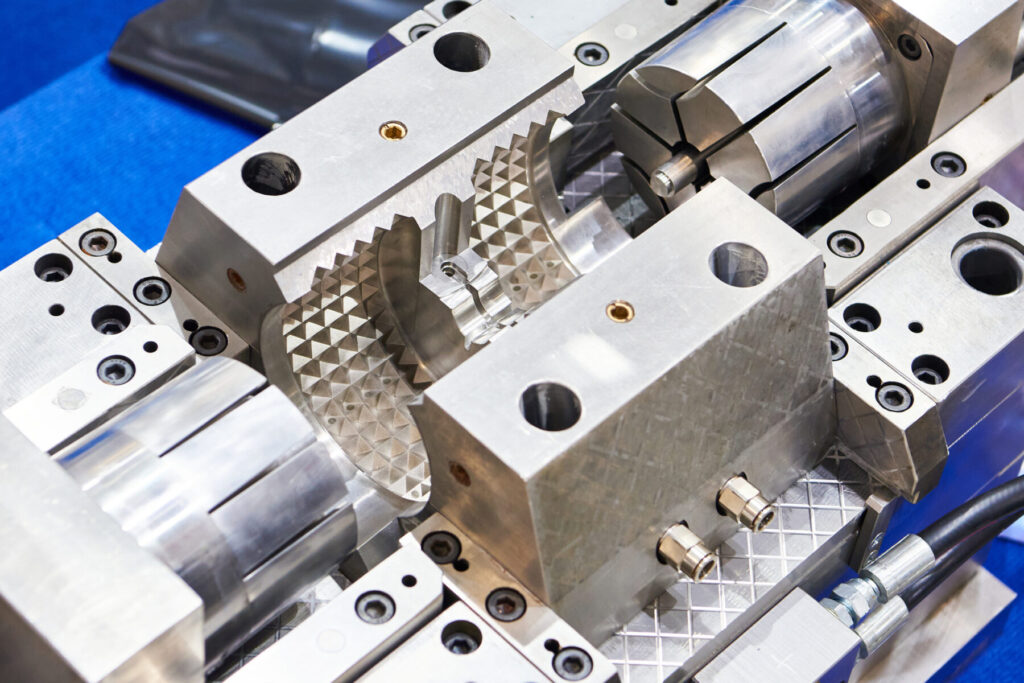

Injection Molded Part Design

- Experience with a variety of mold layouts to reduce cost

- Mold Flow simulation analysis

- Expert materials selection per application

- Custom material design

- Integrated features to minimize assembly costs

- Custom component design for high volume production using injection molding

- Large network of quick turn manufacturers

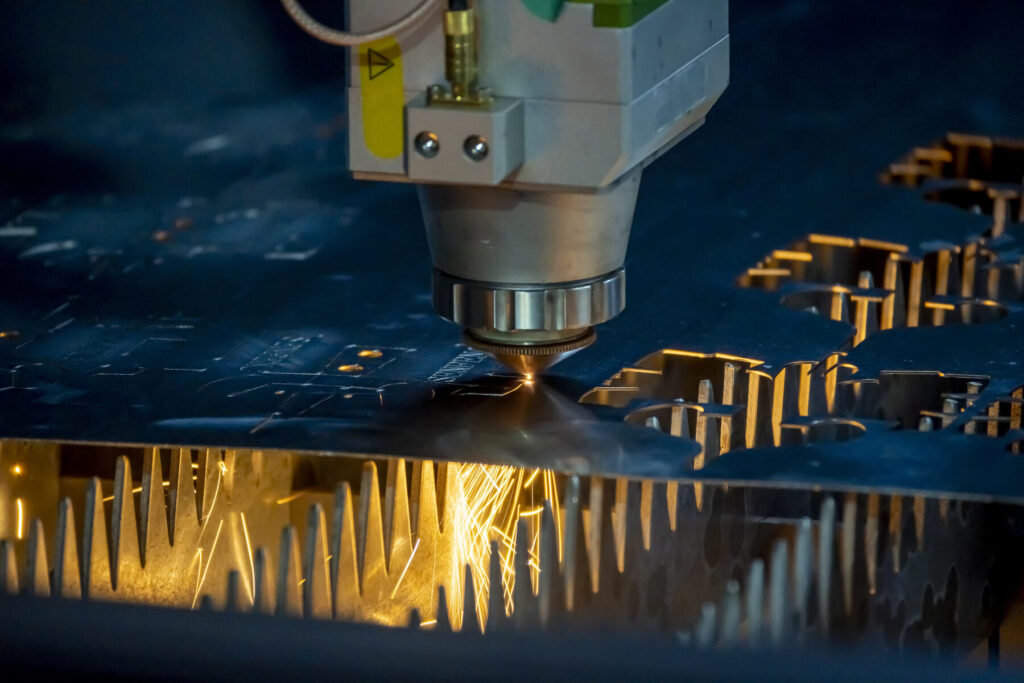

CNC and Sheet Metal Part Design

Sparx can design an optimized part for any major manufacturing process.

- Multi-axis CNC milling/turning component design

- Cost effective and detail oriented approach to manufacturing design for maximum precision and efficiency

Contact Us

With a focus and adherence to design for manufacturability (DFM), design for test, and a highly parallel workflow, Sparx is capable of quickly moving a project from conceptual sketch to production.